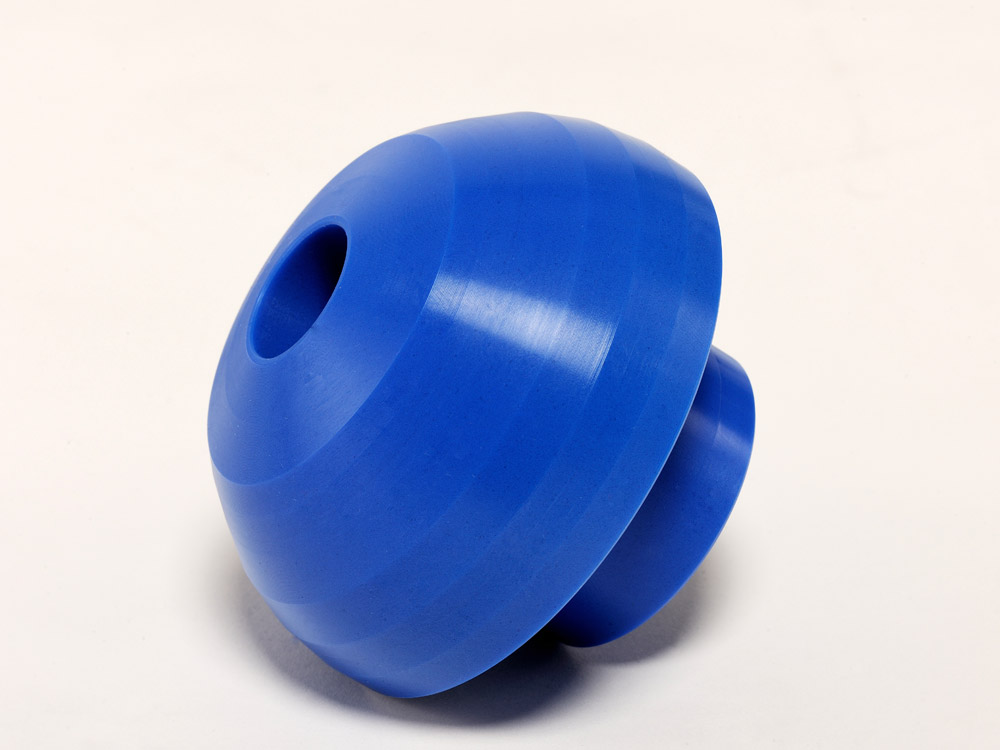

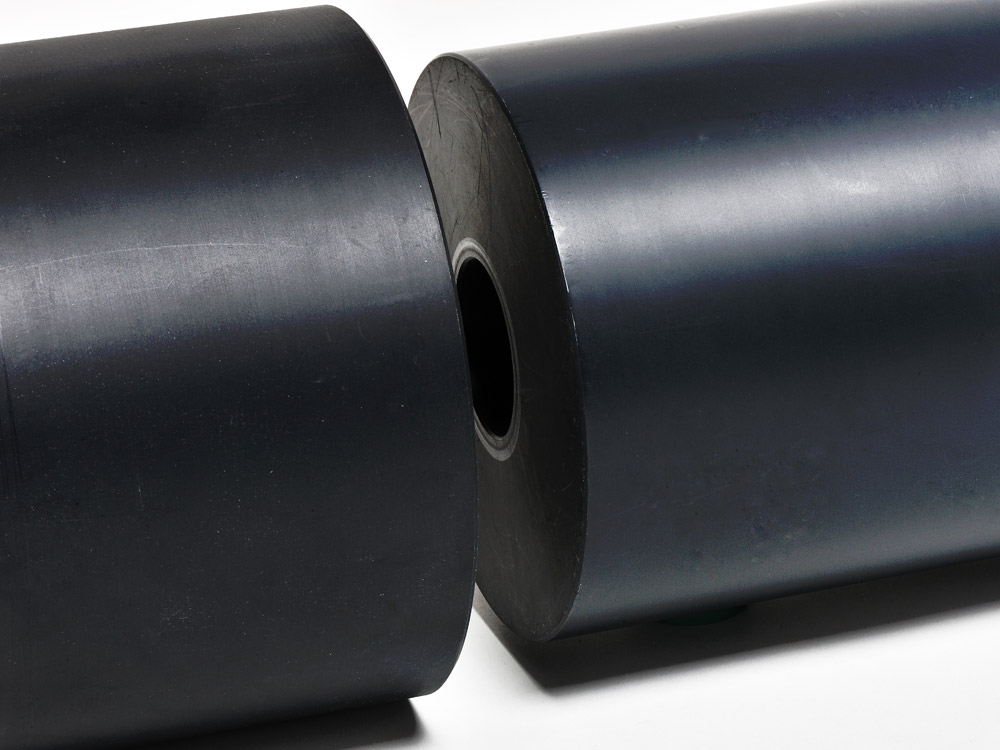

PTFE (Polytetrafluoroethylene)

Exceptional performance in sliding, chemical resistance, and extreme conditions

PTFE is one of the highest-performing materials for critical industrial applications.

It is non-toxic, highly resistant to chemical agents (except hydrofluoric acid and strong bases), does not absorb water, offers excellent dielectric properties, and has one of the lowest coefficients of friction available.

Tecno Plastic machines PTFE in multiple formulations, developed to ensure superior performance in the most demanding industries.

PTFE grades we machine

Virgin PTFE

Pure, inert PTFE, resistant to high temperatures and featuring non-stick properties. Ideal for corrosive, food-grade, or medical environments.

Advantages

Maximum sliding performance, chemical resistance, dielectric properties, food-contact suitability.

Application fields

Pumps and fluid systems, chemical, medical, food processing, oil & gas, mechanical, railway, bottling.

PTFE + Glass Fiber (25%)

Glass-fiber-filled PTFE to increase wear resistance and rigidity. More stable under load than virgin PTFE.

Advantages

Improved wear resistance, reduced deformation, good dimensional stability.

Application fields

Pumps and fluid systems, chemical, medical, food processing, oil & gas, mechanical.

PTFE + Steel

Filled with metal powders to improve compressive strength and conductivity. Effective in static and thermally demanding environments.

Advantages

High compressive strength, thermal and electrical conductivity, good mechanical stability.

Application fields

Chemical, medical, oil & gas, automation, electronics, food processing.

PTFE + Carbon (25%–35%)

Increased wear resistance with excellent thermal and electrical conductivity, while maintaining low friction thanks to graphite.

Advantages

High mechanical strength, enhanced conductivity, low friction.

Application fields

Fluid systems, chemical, medical, oil & gas, automation, mechanical engineering.

PTFE + Bronze (40%–60%)

Improves compressive strength and sliding properties. Offers good wear resistance and conductivity, with lower chemical resistance.

Advantages

Excellent mechanical strength, high wear resistance, compressive strength, and sliding performance.

Application fields

Oil & gas, fluid systems, automation, semiconductors.

PTFE + Al₂O₃ (20%)

Excellent wear resistance and dynamic friction performance, with lower compressive strength. Suitable for low-speed and precision movements.

Advantages

Excellent sliding properties, good wear resistance, medium rigidity.

Application fields

Industrial automation, textile, medical, chemical industries.

PTFE + MoS₂ (Molybdenum Disulfide)

Provides excellent non-stick properties, resistance to deformation, and very low static friction. Ideal for abrasive environments.

Advantages

Excellent sliding performance, good rigidity, advanced anti-stick properties.

Application fields

Chemical, fluid systems, power plants, automation.

PTFE + Graphite (15%–25%)

Improves thermal and electrical performance and wear resistance while further reducing friction. Ideal for static and technical environments.

Advantages

Excellent conductivity, reduced friction, good stability.

Application fields

Fluid systems, automation, electronics, chemical, food processing.

PTFE Bronze 40 %+MoS₂

Material with excellent wear resistance, improved thermal properties, and reduced deformation under load.

Advantages

Particularly suitable for the construction of tanks and chemical processing systems.

Application fields

Chemical, food, medical and pharmaceutical, power plant, offshore, oil & gas, mechanical, industrial automation, electrical and semiconductor.

Contact us

Discover our solutions: lighter, more efficient, higher-performing. Fill out the form. Fill out the form