Polyamides

Versatility, strength, and performance for complex industrial applications

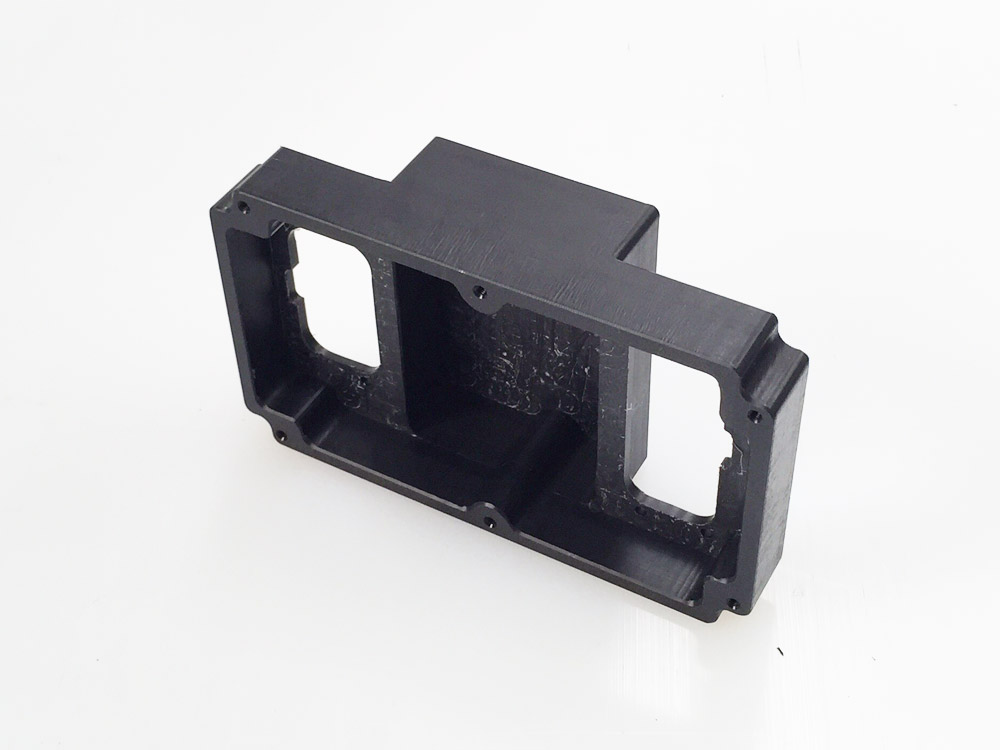

Polyamides (nylon) represent one of the most widely used families of thermoplastic materials in the industrial sector.

Thanks to their excellent mechanical properties, wear resistance, and versatility, they are the ideal choice for components subjected to dynamic loads.

They are available in numerous variants with specific characteristics: self-lubricating, reinforced, high-rigidity, or enhanced dimensional stability.

Polyamide grades we machine

PA6 (Polyamide 6)

PA6 is a semi-crystalline polyamide widely used for its versatility.

It offers a good balance between mechanical strength, rigidity, and impact absorption. It also provides good electrical insulation properties and moderate chemical resistance.

It is easy to machine and suitable for many general industrial applications.

Advantages

Good mechanical strength, fair electrical insulation, versatile and easy to machine.

Application fields

Slides, rollers, guides, pulleys, wheels, profiles in general mechanical environments.

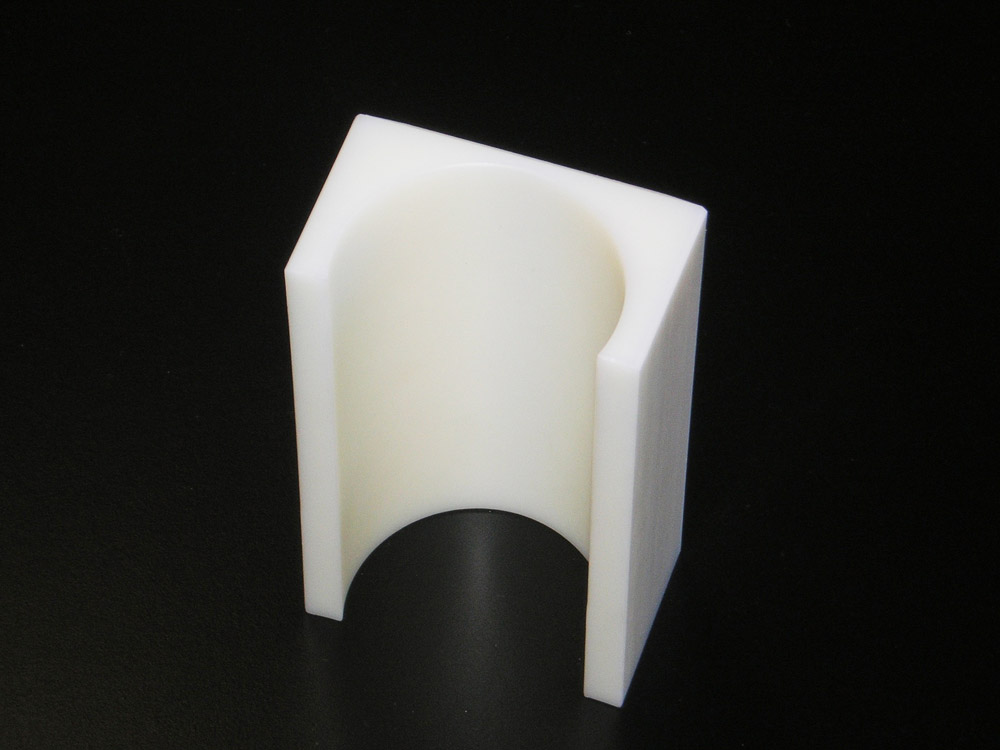

PA6 G (Cast Nylon)

PA6 G is a cast nylon with a more homogeneous crystalline structure compared to extruded PA6.

This results in improved impact resistance, reduced moisture absorption, and good dimensional stability. It is particularly suitable for machining large-sized components.

Advantages

Improved impact resistance and lower moisture absorption compared to PA6. Good sliding properties.

Application fields

Mechanical engineering, industrial automation, construction, agriculture, transportation, oil & gas.

PA6 G + Oil (Self-lubricating)

A cast PA6 version containing solid lubricants dispersed throughout the material. It maintains the mechanical properties of PA6 G while offering reduced friction and extended service life. Ideal for components subject to continuous wear or frequent sliding.

Advantages

Low coefficient of friction, increased wear resistance, suitable for continuous motion.

Application fields

Rollers, pulleys, sheaves, agricultural components, and industrial machinery.

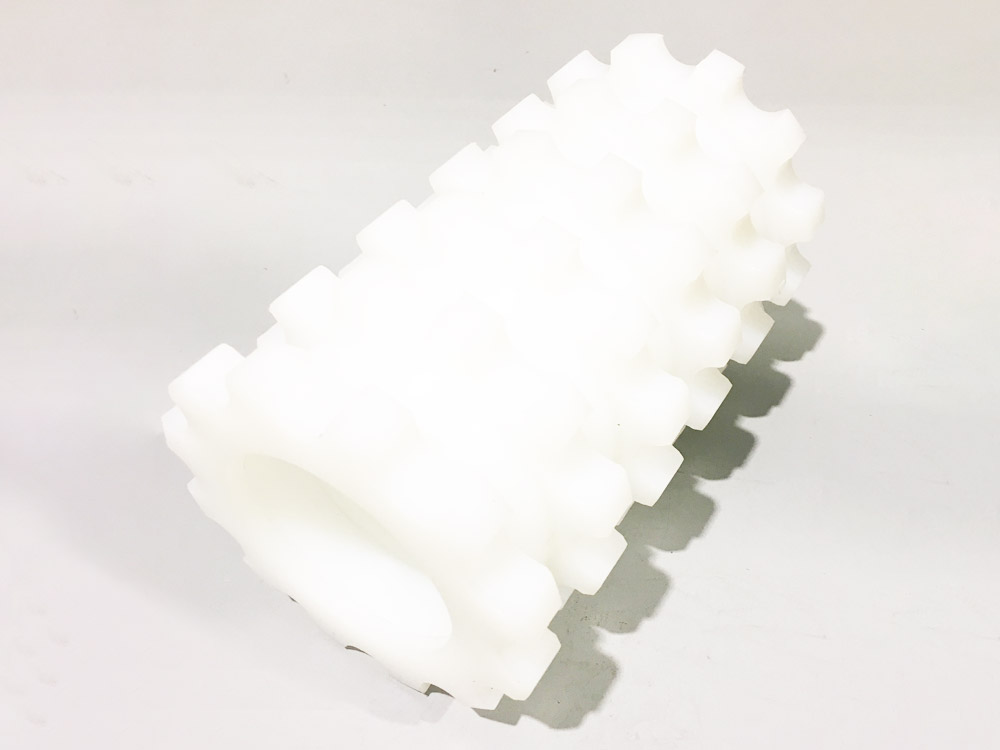

PA6 G + MoS₂ (with molybdenum disulfide)

Polyamide reinforced with MoS₂ to enhance wear resistance, rigidity, and sliding properties. Particularly suitable for applications in harsh environments where superior performance and dry-running capability are required.

Advantages

Improved sliding performance, rigidity, and heat resistance. Self-lubricating and wear-resistant.

Application fields

Bearings, gears, pulleys in heavy industrial systems.

PA6 + GF30 (30% glass fiber)

Polyamide filled with 30% glass fiber to increase rigidity, thermal stability, and tensile strength. Not recommended for friction or sliding applications, but excellent for structural and deformation-resistant components.

Advantages

High rigidity, tensile strength, thermal and chemical resistance. Not suitable for sliding applications.

Application fields

Gears, mechanical structures, components in automation and chemical industries.

PA6.6 (Polyamide 6.6)

A polyamide with higher crystallinity than PA6, providing superior mechanical strength, excellent rigidity, higher heat resistance, and reduced deformation under static load. Ideal for machining on automatic lathes.

Advantages

Greater rigidity, heat resistance, and wear resistance compared to PA6. Good creep resistance.

Application fields

Cams, bushings, valves, gears in chemical or medical environments.

PA6.6 + GF30

A glass-fiber-reinforced version of PA6.6 designed to improve mechanical strength, chemical resistance, and dimensional stability. Ideal for high-temperature environments or structural load applications. Not suitable for dynamic friction.

Advantages

Superior mechanical strength, thermal and electrical dimensional stability. Limited suitability for dynamic applications.

Application fields

Automotive, agriculture, chemical plants, and heavy industrial systems.

PA12

A polyamide characterized by very low moisture absorption, good dimensional stability, and impact resistance. It offers excellent machinability and stable performance even in humid environments. Suitable for electrical and food-grade applications.

Advantages

Very low hygroscopicity, excellent dimensional stability, impact resistance, and good sliding properties.

Application fields

Components in humid environments, food processing, electrical, aerospace.

PA4.6

A high-performance polyamide with superior rigidity and creep resistance, even at elevated temperatures. Ideal for critical environments where standard materials cannot ensure long-term mechanical stability.

Advantages

High rigidity, excellent creep and heat resistance, even in severe conditions.

Application fields

Electronics, semiconductors, aerospace, automation, and high-temperature mechanical applications.

Contact us

Discover our solutions: lighter, more efficient, higher-performing. Fill out the form. Fill out the form