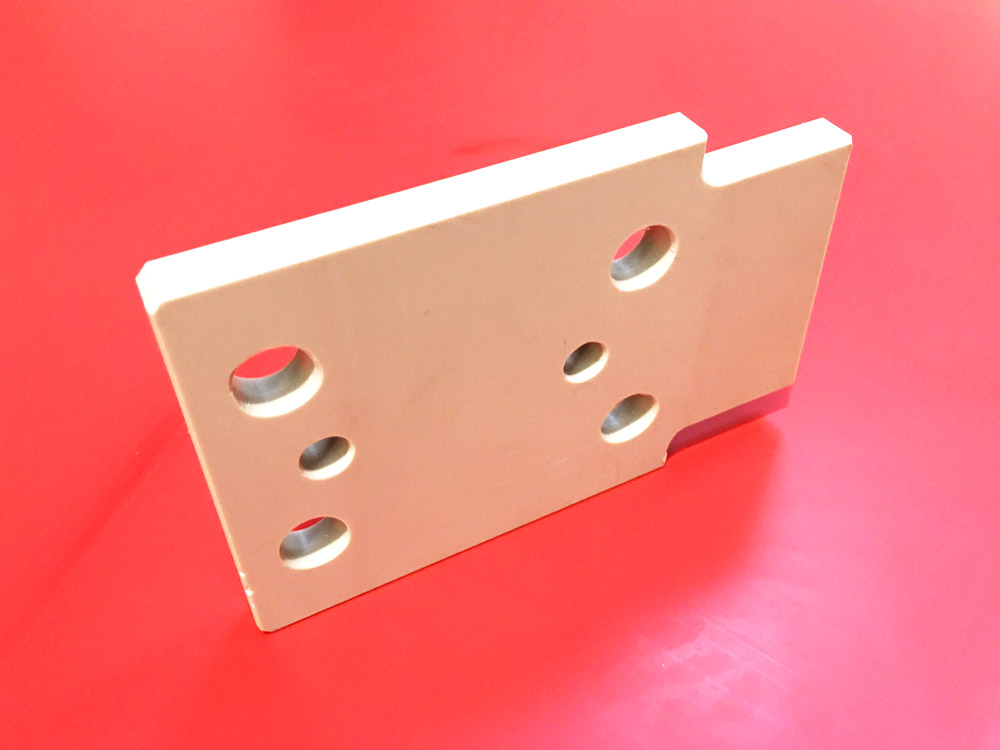

PEEK (Polyether Ether Ketone)

Maximum thermo-mechanical resistance for critical high-performance applications

PEEK is one of the highest-performing semi-crystalline engineering polymers available. It guarantees dimensional stability, rigidity, and excellent mechanical and chemical resistance even under extreme operating conditions.

Non-flammable (UL94 V-0), it retains its structural properties up to 250°C, with outstanding resistance to fatigue, radiation, wear, and saline environments.

It is ideal for applications where metal is no longer sufficient but lightweight performance is essential.

PEEK grades we machine

Virgin PEEK

A pure, ultra-high-performance engineering polymer. It retains its mechanical properties even in aggressive environments, offering exceptional tensile, flexural, and compressive strength.

Advantages

Unchanged up to 250°C, high chemical and dimensional stability, excellent electrical insulation and wear resistance.

Application fields

Aerospace, medical, chemical, oil & gas, food processing, automotive, semiconductors, mechanical engineering.

PEEK + GF30 (30% glass fiber)

Glass fiber reinforcement significantly increases stiffness, compressive strength, and thermal stability, making it suitable for fixed structural components.

Advantages

Extreme rigidity, dimensional stability, and mechanical resistance in high-temperature environments.

Application fields

Aerospace, oil & gas, chemical, automotive, medical.

PEEK MOD (Graphite + PTFE + Carbon filled)

An optimized compound for dynamic applications, offering low friction, high thermal resistance, excellent wear performance, and stability up to 260°C.

Advantages

Low coefficient of friction, exceptional sliding performance, and wear resistance under dynamic loads.

Application fields

Mechanical engineering, automation, oil & gas, medical, chemical, electronics, aerospace.

PEI

High-performance material with excellent mechanical, thermal, and electrical properties, characterized by high dielectric strength, dimensional stability, and excellent resistance to hydrolysis.

Advantages

Reliable over a wide temperature range, it is suitable for use in structural components, coils, and insulating elements.

Application fields

Electrical and semiconductor, aerospace, medical and pharmaceutical, food industry.

PES

This high-performance polymer is suitable for applications with operating temperatures up to 150 °C.

Advantages

With high mechanical strength, rigidity, and resistance to hydrolysis, it is ideal for use in connectors, spools, valves, and pump housings.

Application fields

Pumps and fluid handling, chemical, medical and pharmaceutical, electrical and semiconductor.

PVDF

Thermoplastic material with excellent physical and chemical properties. It can be used under high-temperature conditions and in aggressive environments and is characterized by low flammability.

Advantages

Excellent abrasion resistance and a low coefficient of friction. It features good mechanical properties and excellent dimensional stability.

Application fields

Chemical, medical and pharmaceutical, power plant, offshore, oil & gas, electrical and semiconductor, food industry.

PSU

Non-crystalline, rigid thermoplastic material, often used as an alternative to polycarbonate when higher resistance to temperature and chemical agents is required.

Advantages

Good resistance to deformation and excellent dimensional stability.

Application fields

Food industry, chemical, medical and pharmaceutical, electrical and semiconductor, mechanical.

PPS

Rigid material with high dimensional stability, suitable for continuous operation at elevated temperatures. If not properly treated, it is particularly sensitive to UV radiation.

Advantages

High chemical and mechanical resistance, excellent electrical properties, very low linear thermal expansion coefficient, high purity, and a high degree of crystallinity.

Application fields

Chemical, electrical and semiconductor, pumps and fluid handling, power plant, offshore, oil & gas, aerospace.

Contact us

Discover our solutions: lighter, more efficient, higher-performing. Fill out the form. Fill out the form